|

Minimums

& Maximums are most useful when it comes to purchasing merchandise

and distributing that merchandise from a central warehouse to the

stores. As we’ve mentioned, a chain of 40 stores has to deal

with half a million stocking decisions to keep its operation running.

There is simply no way to make these decisions correctly without

automation. The better a retailer becomes at using Minimums &

Maximums to control purchasing and distribution, the fewer inter-store

transfer he will have to make. Of course no distribution system

can reduce the margin of error completely (customers are, after

all, highly unpredictable) so it becomes necessary to use Automatic

Transfers to fully optimize inventory.

The final step in achieving optimal inventory is balance, or distributing

existing stock among your stores in order to maximize sales. No

two stores will ever have identical sales. Even assuming that two

stores are in the same economic zone and serve the same demographic

base, one manager may decide to highlight a certain style of boot

in the display window while the other one doesn’t, or one store

may have an outstanding saleswoman who really knows how to push

tennis shoes while another store may have someone who is very good

at selling handbags. In most cases, however, economic and demographic

factors are enough to create major differences in the sales patterns

of different stores. The goal of the retailer, even after every

effort has been made to only purchase the stock that is needed,

is to constantly monitor sales and move merchandise to where it

replenishes a sale that has been made. We do this through Automatic

Transfers.

XpertMartTM

allows you to balance inventory between any two stores. You can

select, for example, Store #12 and Store #35, and ask the system

to create Automatic Transfers between these two stores. XpertMartTM

will look for items in Store 12 that are above their Minimum and

below their Minimum for Store 35 and transfer enough items to cover

the Minimum. However, an Automatic Transfer will never ship items

out if it will cause the stock of that item to fall below its Minimum.

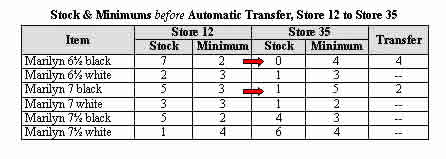

In the table above, there are several examples that illustrate these

rules. In the first item in the table, the Marilyn 6½ black

dress sandal, XpertMartTM will transfer out 4 pairs from Store 12,

where it is overstocked, to store 35, where it is understocked.

Notice that only 4 pairs are sent out and not 5, because only 4

additional pairs are needed for Store 35 to cover its Minimum. In

the second example, no pairs of the Marilyn 6½ white sandal

are shipped out because Store 12’s stock is below its Minimum

and therefore cannot afford to send items to Store 35. Similarly,

in the third example, only 2 pairs of the Marilyn size 7 black sandal

are shipped out to Store 35, because to send any more would mean

Store 12 is understocked as is the case with the next example, the

size 7 white sandal. In the last two cases, no transfer is necessary,

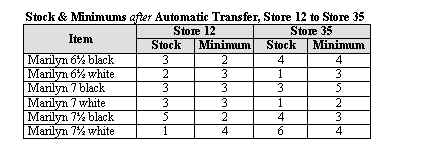

as Store 35 is overstocked. The new stock levels after the transfers

are complete are shown in the table below. XpertMartTM

allows you to balance inventory between any two stores. You can

select, for example, Store #12 and Store #35, and ask the system

to create Automatic Transfers between these two stores. XpertMartTM

will look for items in Store 12 that are above their Minimum and

below their Minimum for Store 35 and transfer enough items to cover

the Minimum. However, an Automatic Transfer will never ship items

out if it will cause the stock of that item to fall below its Minimum.

In the table above, there are several examples that illustrate these

rules. In the first item in the table, the Marilyn 6½ black

dress sandal, XpertMartTM will transfer out 4 pairs from Store 12,

where it is overstocked, to store 35, where it is understocked.

Notice that only 4 pairs are sent out and not 5, because only 4

additional pairs are needed for Store 35 to cover its Minimum. In

the second example, no pairs of the Marilyn 6½ white sandal

are shipped out because Store 12’s stock is below its Minimum

and therefore cannot afford to send items to Store 35. Similarly,

in the third example, only 2 pairs of the Marilyn size 7 black sandal

are shipped out to Store 35, because to send any more would mean

Store 12 is understocked as is the case with the next example, the

size 7 white sandal. In the last two cases, no transfer is necessary,

as Store 35 is overstocked. The new stock levels after the transfers

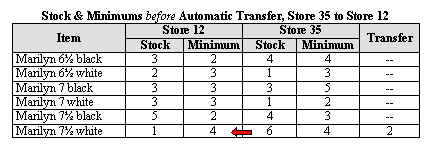

are complete are shown in the table below.  The

process could also go the other way, with Store 35 sending all items

above Minimum to cover inventory gaps in Store 12, for example,

sending 2 pairs of the size 7½ white Marilyn sandals to Store

12. Balancing inventory among these two stores will increase sales

by reducing stock-outs—all without having to order new merchandise!

Balancing inventory will also accelerate rotation, as items will

sell faster, particularly if the alternative is placing an order

with a vendor with long delivery times. The

process could also go the other way, with Store 35 sending all items

above Minimum to cover inventory gaps in Store 12, for example,

sending 2 pairs of the size 7½ white Marilyn sandals to Store

12. Balancing inventory among these two stores will increase sales

by reducing stock-outs—all without having to order new merchandise!

Balancing inventory will also accelerate rotation, as items will

sell faster, particularly if the alternative is placing an order

with a vendor with long delivery times.

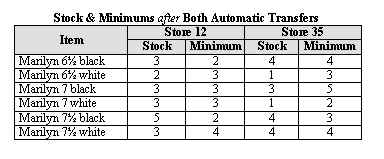

Let’s

examine what these transfers have done to our inventory. Prior to

the Automatic Transfers, we had a total of 36 items in stock between

the two stores (for the 6 size & color combinations shown above).

Of these 36 items, 15 were overstocked, i.e. over their Minimum—that’s

over 40%. Furthermore, we were also understocked by 15 items. Definitely

sub-optimal inventory in both cases. Now, of a total of 12 possible

supply decisions (6 size/color combinations * 2 stores), the system

took 3 supply actions, transferring a total of 8 items. We still

have a total of 36 items, only this time, we are only overstocked

by 5 items. With these three simple transfers, our excess inventory

dropped from over 41% to just under 14%. Similarly, we are now only

understocked by 7 items instead of 15 so that our merchandise shortage

as dropped form over 41% to just under 20%. As we can see from this

example, a little bit of fine-tuning can yield major improvements

in our inventory optimization. This example took place in a total

universe of 12 supply decisions—now imagine the consequences

in a total universe of 500,000 supply decisions!

There

is also the option of balancing inventory across the entire chain,

in which case the system will look for opportunities to move stock

in every store. The advantage of placing Automatic Transfers two

stores at a time is that it gives the user greater control. It may

not be cost effective, for example, to balance inventory between

two stores that are in different cities, or between two stores that

carry very different merchandise. Automatic Transfers are ideal

for balancing inventory between two stores that are in close proximity

with similar merchandise.

Some

retailers are afraid of using automation to manage their distribution

system because they are afraid of losing control over their operation.

The nightmare scenario is trucks full of merchandise crisscrossing

the country on some computer’s orders. The fear is unfounded.

XpertMartTM will always give the user the opportunity to review

every Transfer Order before it is executed. This way the user has

complete freedom to edit or veto any Transfer Order the system generates.

Automatic Transfer Orders are really Automatic Transfer Suggestions,

in this regard. All XpertMartTM is doing at this point is simplifying

the decision-making process by concentrating the right data in the

hands of the user.

You

will never appreciate all the little cases of “one blue pair

of this in size 7 and one pair of those in brown size 8.5”

the system will “pull up” and how impossible it would

be to do this by hand until you actually have one of these suggested

transfer reports in your hands. You may think this document has

taken too much time over-analyzing one pair of style ABC in blue

at store 42. This may seem absurd as you would never have the time

to do this analysis. The point here is that all you have to do is

set the criteria and XpertMartTM whizzes through the 500,000 or

2,000,000 decisions and makes them for you. When you see all of

the items that need to be transferred and look the sale prices totals

on the report, you will see how XpertMartTM pays for itself.

Probably

the most dramatic case we have ever seen was with a client of ours,

a chain of 30 shoe stores. The year before they started working

with us, store managers set Minimums manually; in other words, they

were in no way based on actual sales trends. Once we helped them

automate their chain, the software began calculating and re-calculating

Minimums based on actual sales. On a Saturday night, five days before

Christmas, we realized that each of their 30 stores had, on average,

sold 50% of its stock during this peak season. Store managers were

able to restock their stores by the following Monday morning without

consulting senior management, solely based on Minimums. This way

their stores optimized their inventory in time to take advantage

of the 2½ days left before Christmas. Managers later told

us that “it’s as if we had two holiday seasons that year!”

|

|