Matching Out Slips & In Slips

Chapter Topics

XpertMatch™

Transfer Reports

Correction Slips

XpertMatch™

In the previous chapter we discussed how during inter-store

transfers, stores sending merchandise make Out Slips while stores

receiving merchandise make In Slips. In order to ensure tight control

over the process and make sure inventory is not lost in transit, In

Slips are linked to Out Slip through the Out Slip Number, though the

receiving store cannot see which merchandise was sent by the store of

origin.

Control comes through a two step process called XpertMatch™.

During this process the system: 1) looks to match all Out Slips with

corresponding In Slips, and 2) looks for discrepancies between items

reported as sent in the Out Slip and items reported as received on the

In Slip. In other words, XpertMatch™

quickly tells you whether all transfers successfully arrived at their

intended destination and whether the correct merchandise was received.

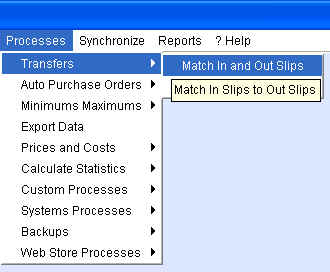

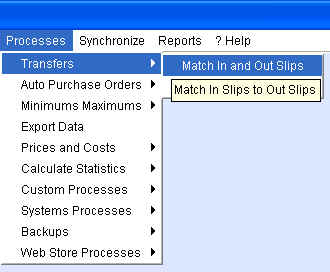

To run the XpertMatch™ process, go to

Processes>Transfers>Match In and Out Slips:

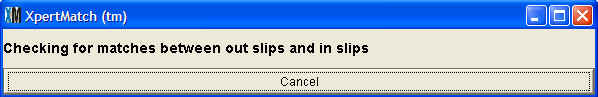

The process will run automatically and you will see a window detailing

the system's progress:

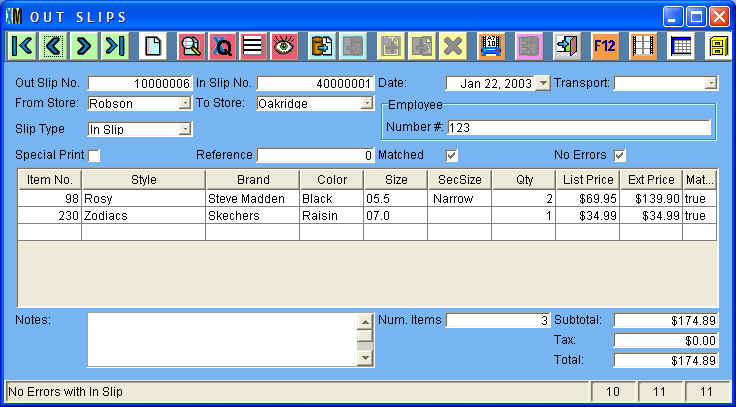

Once the process is finished, you can open the

Documents>Transfers>Out Slips catalog and view the results. Every

Out Slip in the catalog has two checkboxes in addition to the usual

transaction information. The "Matched" checkbox indicates whether a

corresponding In Slip was found for the Out Slip. If it was, the box

will be checked and the In Slip number will be automatically entered in

the "In Slip No." field. If the Matched checkbox is not checked, then

the merchandise is still in transit--either because the receiving store

is several days away or because the shipment has in fact been lost or

has not properly recorded.

If the Out Slip is matched with an In Slip, the system checks every

line in the Items Area for

errors. An error is a mismatch in any of the following: the Style,

Size, Color, Second Size and Quantity. If there is a discrepancy

between what is on the Out Slip and what is on the In Slip in any one

of these five variables, the system considers it an error and writes

"false" in the Matched column. If all five of these dimensions are the

same, the system writes "true" in the Matched column. If all lines in

the Items Area are "true" then the "No Errors" checkbox is checked.

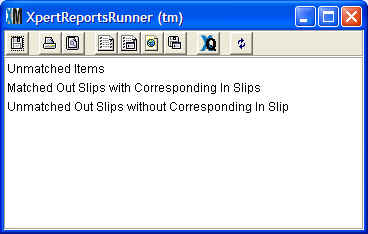

Transfer Reports

In a large chain environment where dozens of transfers are

made a day it is not practical to search the

Documents>Transfers>Out Slips catalog to find those transfers

that are problematic. There are reports you can run that quickly

identify transfers that require management attention. To run these

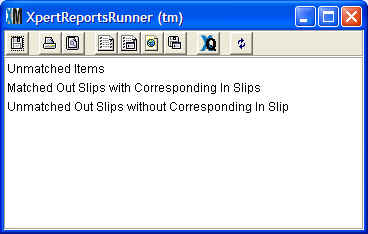

reports, go to Processes>Transfers>Transfer Reports. A window displaying reports are available to run

will appear:

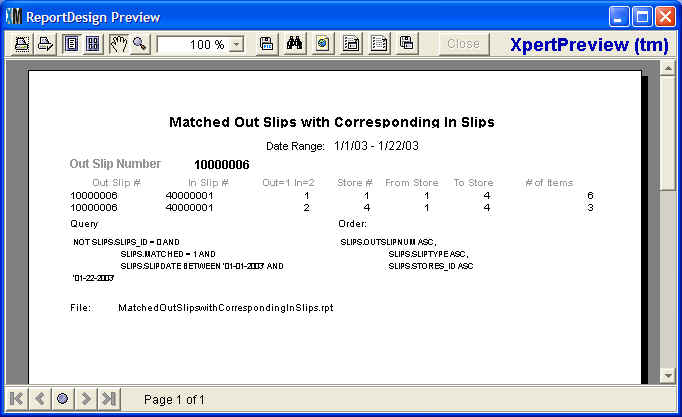

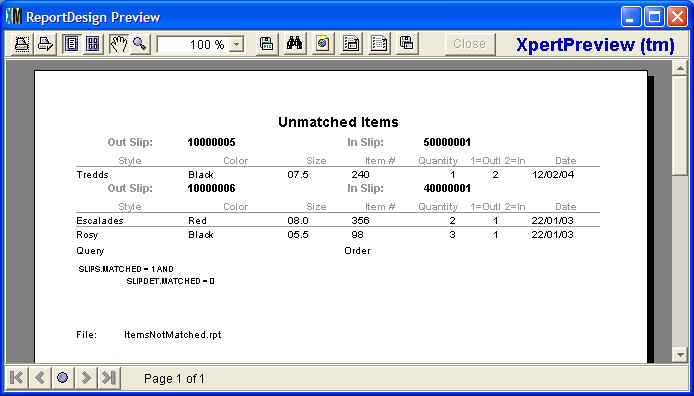

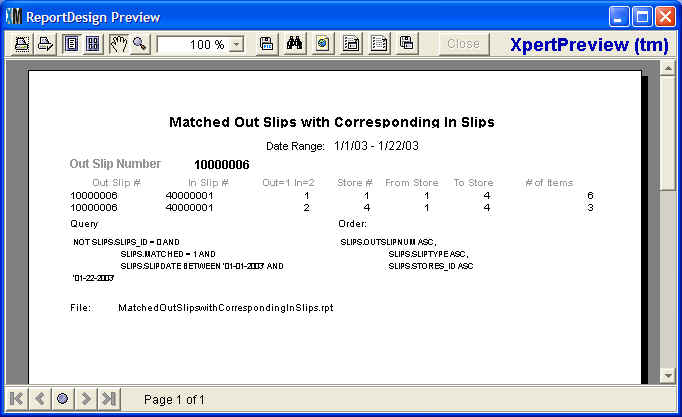

The Matched Out Slips with Corresponding In Slips report shows all Out

Slips that were successfully matched with In Slips. In the image below,

we see the sample Out Slip we made

(10000006) matched with the sample In Slip

we made (40000001). We can also see that whereas there were 6 items in

the Out Slip there were only 4 in the In Slip:

The Unmatched Out Slips without Corresponding In Slip report shows the

opposite: those Out Slips which have yet to be matched. These are the

Out Slips that reuquire immediate management attention. You should find

the unmatched Out Slips in the Documents>Transfers>Out Slips

catalog and see whether the merchandise is justifiably still in transit

(the receiving store is far, the mode of transport is slow, etc.) or

whether there is in fact a problem.

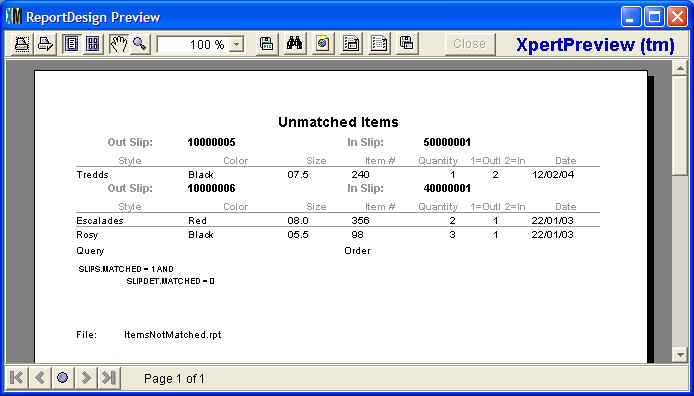

The other useful report that requires management attention is the

Unmatched Items report. This report lists all items found on matched

Out Slips that are on the Out Slip but not on the corresponding In Slip

and vice-versa. In the exmaple below we see that the 3 Rosy Balck 5.5

pairs were not properly matched (only 2 were received) and the 2

Escalades Red 8.0 were also not matched (none were reported as

received).

Managers should use this report to control merchandise loss. By looking

in the Documents>Transfers catalogs they can find the employees

responsible for making both the Out Slip and In Slip in question and

determine where the mistake was made. Once they have, they can proceed

to fix the mistake by making Correction Slips.

Correction Slips

In keeping with our Philosophy

of Control, if a mistake was made on an Out Slip or In Slip the

original slip cannot be deleted or edited. Rather a new Document, a

Correction Slip, needs to be made. This way there is always an audit trail that can be traced.

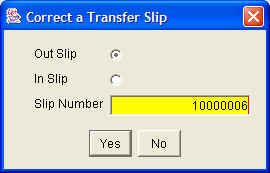

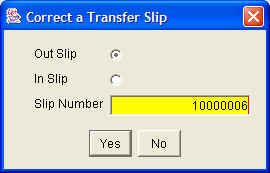

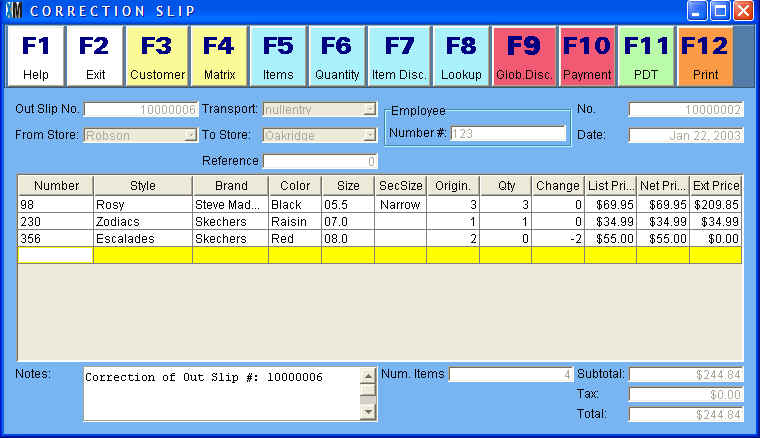

To make a Correction Slip, go to

Transactions>Transfers>Correction Slips. You will see this window

appear:

Select whether you are correcting an Out Slip or In Slip. Then enter

the Document Number for the

Slip being corrected. A Transaction screen populated with the data on

the original Slip will appear:

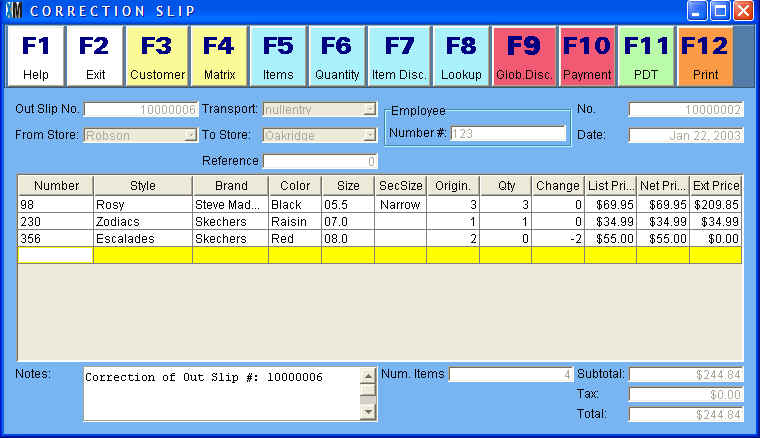

The "Origin." column displays the quantities on the original slip. If

you want to modify one of these, enter a new quantity in the "Qty."

column. The difference between the original and modified quantities

will be automatically displayed under the "Change" column. You can also

add a new item that was not on the original Slip. Notice that the Notes

area is automatically filled in with the text "Correction of Out Slip

#: 10000006".

In the example above, the 2 pairs of Escalades Red 8.0 shoes are being

removed from the original Out Slip.

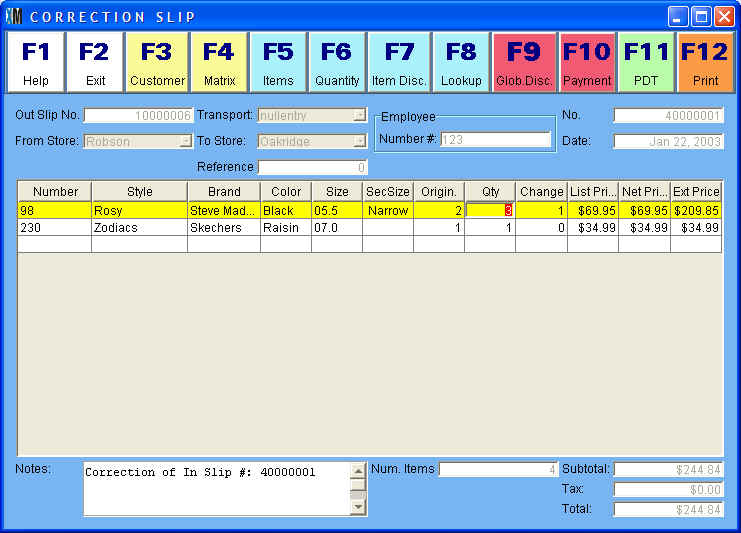

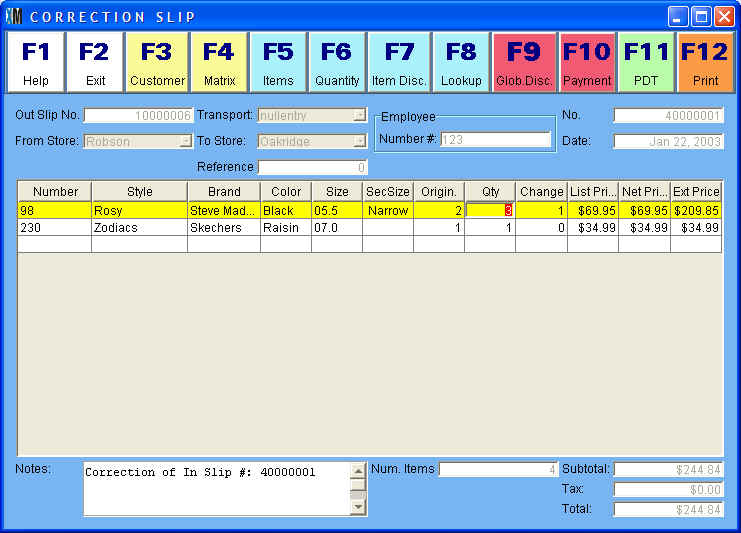

In the exmaple below, the quantities received in the original In Slip are being modified. Instead of

receiving 2 pairs of Rosy Black 5.5, the original In Slip is being

corrected as showing that 3 pairs were received.

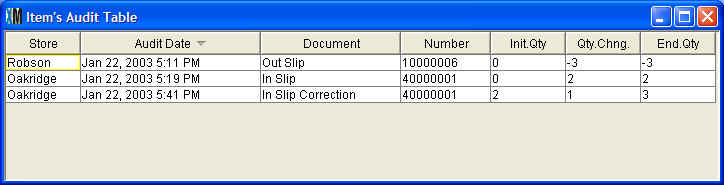

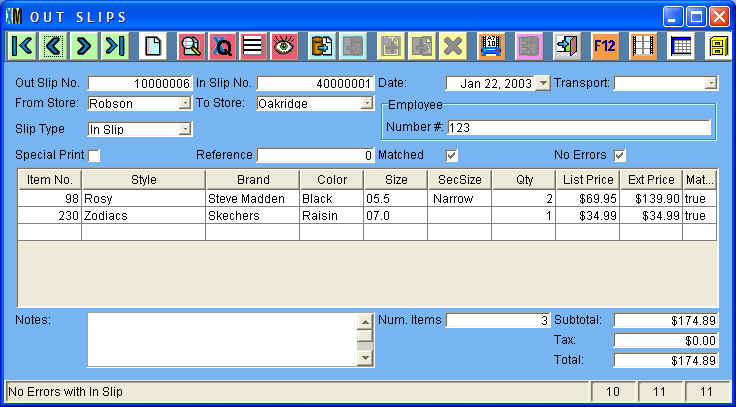

The two errors we intentionally planted in the original Out Slip have

been corrected. When the XpertMatch™

process is run again, the Out Slip on file now looks like this:

The Out Slip has been Matched and there are No Errors now. More

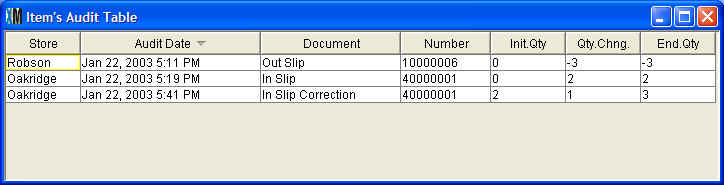

importantly, there is a clear audit trail showing every change that has been made to

the inventory of each item. The audit table

for Item #98, the Rosy Black 5.5 shoe looks like this:

We can see the original Out Slip

(10000006) that subtracted 3 pairs from the Robson store and the

original In Slip (40000001) that added

2 pairs to the Oakridge store. We also see the In Slip Correction that

added the third paird ot the Oakridge store. All items are now properly

accounted for.

Copyright © 2004 Dinari Systems LLC