XpertMart (mr) Autodistribution

Autodistribution can be used to replenish stores from one or more

warehouses or it can be used to balance inventory between various

stores and warehouses.

The Autodistribution

module's purpose is to distribute merchandise in the most optimum

quantities between two or more inventory locations. Optimum inventory

distribution is that which takes stock as close as possible to the

quantities established as minimums or ideal inventory. That is to avoid

as much as possible, that an item's on hand stock be either below or

above the established minimum stock quantity for that store or

warehouse.

The Autodistribution module can

also distribute merchandise in prepacks defined as a box containing a

single style and single color in varying quantities of various sizes.

Origen of the Distributed Merchandise

If you run Autodistribution from the main then you can specify

one, several or all of the warehouses and stores as sources of

merchandise to distribute.

If you run

Autodistribution from a warehouse or store remote then it is

automatically assumed that the store or warehouse will be the source of

the merchandise to distribute.

In any case

the merchandise in stock that is above the minimum established for that

particular warehouse(s) or store(s) is the merchandise that is

available for distribution. The autodistribution module will never

transfer away stock that is needed in the source location for it to

have up to the minimum stock specified.

Destination of the Distributed Merchandise

When you run Autodistribution from the main or any remote

warehouse or store, you can specify one, several or all of the stores

and warehouses as destinations for distributed merchandise.

Type of Merchandise to Distribute

You use the merchandise selector in XpertMart with XpertQuery to

determine if you want to automatically distribute all types of

merchandise or only certain types of merchandise.

Distribution Criteria

In order to assure the most optimum distribution, XpertMart

grades each possible transfer or each individual item from a warehouse

or store to another warehouse or store. The grade is made up of two

parts. First it grades how much a possible transfer would help lower

excess inventory (inventory above the minimum) if any at the origin.

Then it grades how much a possible transfer would help raise the

destinations inventory closer to or exactly to its minimum. The sum of

these two grades it the total grade for that possible transfer. If

there is more than one possible combination of origin and destination

for an identical item, then all possible combinations are graded and

the transfer is made for the option with the highest total grade.

When prepacks are to be distribuited, each item within the

prepack is graded and then the sum of the grades of all the items is

the grade of the prepack. Prepacks are graded against every possible

origin and destination as is done with individual items and the

transfer is made for the origin and destination with the highest grade.

Optionally the autodistribution process can recommend when it

would be most convenient to break a prepack and send individual items

to different stores or warehouses if that would give you the most

optimum distribution.

Further on we explain the grading process in detail and we will show an example of how it works.

Distribution Process

First of all, if any or the stores or warehouses to be used as a

source of merchandise to distribute has prepack stock, then a test is

made to see if any of the prepacks fills the distribution requirements

of any of the destination stores or warehouses. You can configure

Autodistribution to specify the minimum grade that a possible prepack

transfer must have to be sent. Every prepack transfer that meets

this minimum grade will be transferred.

After

distributing any prepacks that can be transferred, Autodistribution

then proceeds to distribute the single items.

Each item available for distribution is sent to the store or

warehouse that gets the highest grade above zero. It does this until

there are no more item available for distribution that are needed at

any store or warehouse.

Distribution Method

If the automatic distribution is run from the main then the

distribution will be done via proposed transfer slips that will be

synched to the warehouses or stores that would transfer out the

merchandise. At the remotes there is the option of processing the

autotransfers which would make an Out Slip for every Proposed Out Slip.

If Automatic Distribution is run from a remote then you can

decide if you want to generate Proposed Out Slips or directly make Out

Slips.

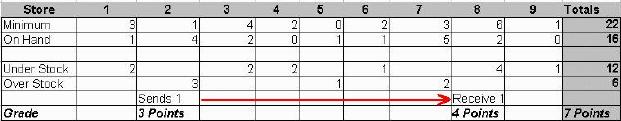

An Example of Grading and Automatic Distribution

To make sure that items are distributed from places where they

are in most excess to the place where they are most needed, XpertMart

grades each possible transfer giving it points so how much it is

overstocked at the point of origin and how much it is understocked at

the point of destination. This actually a very simple system. If the

place of origin the are three items more than the minimum then the

possible transfer is given three points for its origin. If at the

destination the item is four pieces below its minimum then the possible

transfer is given four point for its destination. In this case the

possible transfer has a score of seven points.

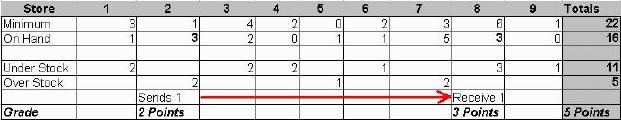

Here we show you a sheet that shows the example of a chain of

nine stores, with the stock and minimums of each. In the totals column

you can see that there is a total of twelve items understocked and a

total of six items overstocked. You can see in the case of the first

transfer that it gets a score of seven points.

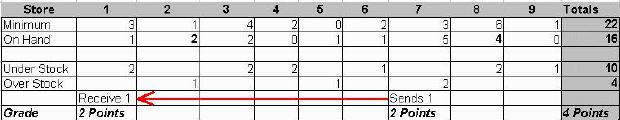

On this second sheet we can see how the inventory is after the

first transfer and which is the second transfer that Autodistribution

would make. You will notice that the transfer gets two points for its

origin and three points for it destination which gives it a total grade

of five points.

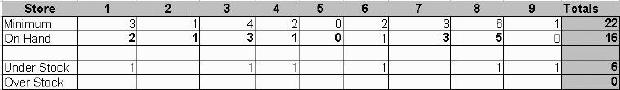

On this third sheet we can see how inventory looks after the

second transfer and what would be the third transfer to be made. You

will notice that the transfer receives two points for its origin and

two points for its destination giving it a total score of four.

On this final sheet we can see how te inventory would be after

transferring all the excess inventory to the stores where it is most

needed.

The result of the automatic distribution is that there is no

longer any overage of stock left of this item and there are only six

pieces understocked instead of the original twelve pieces.

Consider that all of this is done just for one item of a certain

Style / Color / Size / Second Size. XpertMart will do this for the

thousands of articles that you normally handle in a chain of stores.

Prepack Grading

We grade prepacks in a similar fashion to see which origin and

destination is the best. In the case of prepacks it may be that one or

more or the items in the prepack may take the on hand stock over the

quantity established as a minimum or the item being transfered may

already be over the minimum. In these cases we give negative grades or

take away points. If a particular item in the prepack is already at its

minimum level then the item in the prepack will make it go over by one

so we give this item a grade of minus one (-1). If for example a

particular item in the prepack has on hand stock two above minimum then

this item will take the on hand stock to three over minimum so we give

this item a grade of minus three (-3)

The

total grade for the prepack is made up of the sum of the grades of each

of the items in the prepack. Negatives are added to positives. It may

be that several high grades of items will balance out one or more

negative grades.

The objective here is as

stated above: That is to avoid as much as possible, that an item's on

hand stock be either below or above the established minimum stock

quantity for that store or warehouse.

The

prepack transfer that has the highest grade is the prepack transfer

that will be made. In the same fashion as with single items,

Autodistribution will make the transfers of prepacks with the highest

grades until there are no more prepacks available for distribution, or

there are no more items needed at destinations or it only has prepacks

whose transfer would not reach the minimum grade specified in the

configuration as required to make transfer.

Grading to Break a Prepack

There may be cases in which the items contained in a prepack as a

group would so overstock any store it was sent to that it would always

have a low or even negative grade. After doing the automatic transfer

of single items (items not in prepacks) XpertMart Autodistribution

could test to see if it is best to break open a prepack and send

separate items to more than one store. In the same way Autodistribution

has graded possible single items and prepack transfers, in this step it

grades every item in the prepack box against all possible destinations

to see what is the highest grade it can get from every item in the

prepack box. If the prepack gets a high grade in this manner it means

that the needs of several locations would be best met by breaking the

prepack box and sending individual items to different destinations. If

you have configured your system to allow breaking prepacks then

Autodistribution will generate a Prepack Break Document. At the same

time it will include many of the items that are in the prepack box in

the single item transfer slips. (It will only transfer all the items in

the prepack box if they all would receive a positive grade. This is to

avoid overstocking.)

Configuration

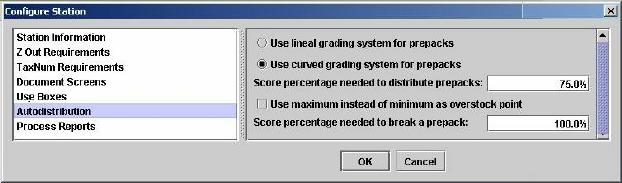

There are some configurable options regarding Autodistribution.

To modify these configuration options you choose Configure /

Configure Station from the main menu as you can see in this screen shot.

Once Configure Station opens you need to select Autodistribution

on the left side as shown in this screen shot.

The first two options are to choose if you want to “Use lineal

grading system for prepacks” or “Grade prepacks on a curve”. We

strongly recommend that you use a curved grading system rather than a

lineal system. All the examples given above were given based on a

curved grading system. The curved system give plus or minus points

based on how much under or over stocked an item is. Thus in the

examples grades of 3 or -2. In a lineal grading system each item would

be either 1 or -1 irregardless of how much under or overstock there was

at a given location.

The third option is to

specify the minimum grade that a prepack must have for it to be

transferred. The grade is expressed as a percentage. If a prepack

has 12 items in it and gets a grade of 12 then it would have a 100%

grade. If a prepack has 12 items and gets a grade of 9 point then it

would have a 75% grade.

The fourth option

will be implemented in the future. In this case you will not subtract

points from a transfer unless the transfer would go over the maximum

defined for the item en this store.

The last

option is the percentage grade the a potential prepack break should

receive before it breaks the prepack to send the loose items to the

stores. If the items that are in the prepack do not get at least this

grade, then XpertMart will not recommend breaking the prepack.

Operation

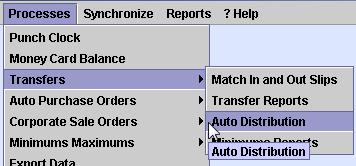

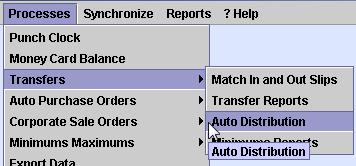

To run Autodistribution you select the option from the main menu

under Processes / Transfers / Autodistribution as can be seen in this

image.

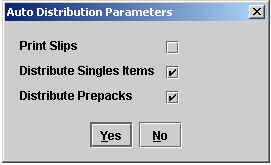

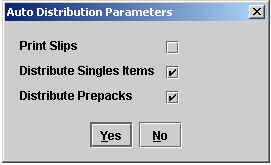

The options that will be displayed are

going to vary depending on whether you run Autodistribution at the Main

or at a Remote. The options will also vary depending on whether you

have configured your system to handle prepacks or not. In this first

screen shot we will see the options presented at the Main when you have

configured to use Prepacks.

In the sample

above you only need to select whether you want to print the transfer or

proposed transfer slips as they are generated or not. Then you select

whether you want to distribute single items or not and in the same

fashion whether you want to distribute perpacks or not. You will get

the most optimum distribution if you choose to distribute both prepacks

and single items at the same time, that is if you are using prepacks in

your company. If you select both single items and prepacks then

Autodistribution will first seek to distribute prepacks and then single

items. (If single items are distributed first there will be less need

for merchandise and it will be harder to find a prepack that can be

transferred that will fill stock needed in the store without going over

the minimum stock specified.)

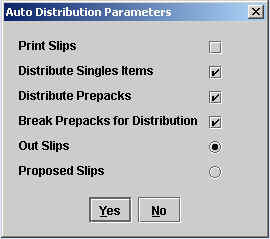

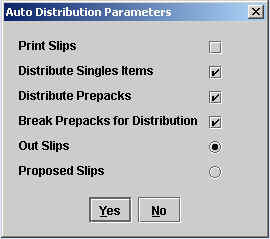

In this second

dialog window we can see what options will be available if

Autodistribution is run from a remote and the system is configured to

handle prepacks.

The first three options

are the same as we explained above. The fourth option allows us to

select whether we want to break prepacks to distribute the single items

in the prepack or not. This option will only be available on

remotes that are configured to track inventory by prepacks. At a remote

we can select whether we want to generate Proposed Out Slips or actual

Out Slips. (At the main you cannot generate Out Slips that is why at

the main Proposed Out Slips will always be generated.)

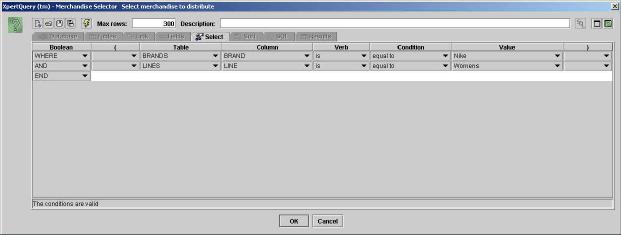

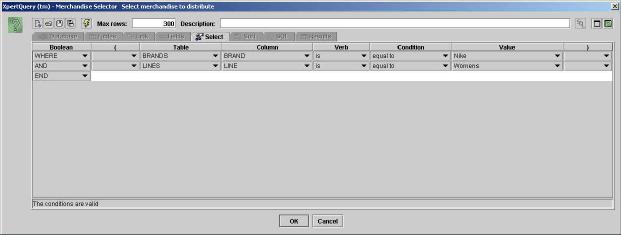

Once you have answered this initial dialog, you will be presented

with the Merchandise Selector so that you can choose what merchandise

to select. The Merchandise Selector looks like this:

With the Merchandise Selector you can choose the merchandise

based on Vendor, Department, Lines, Season or any combination of the

tables of characteristics of the merchandise. If you want to distribute

all kinds of merchandise then all you have to do is click on the Ok

button. Remember, in any case only the merchandise whose on hand stock

is less than the minimum at a destination is going to be transferred.

No merchandise will be distributed that is not above the minimum at the

source location and below minimum at the destination location.

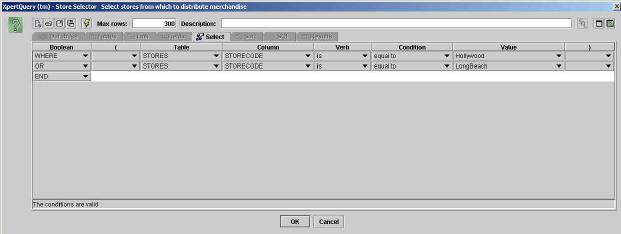

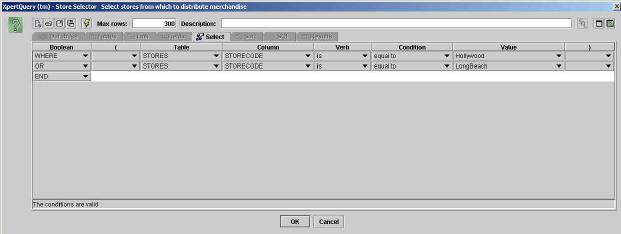

If you run Autodistribution from the main then the merchandise

can come from one or more of the warehouses or stores. If you run this

from the main then you will see the Store Selector so that you can

choose which warehouses or stores will be sources for the merchandise

to distribute.

You can use any of the

characteristics of the stores to choose which stores will be sources

from which to supply merchandise for the distribution. If you want to

send merchandise from all the stores (for example to balance inventory

in all the stores) then all you have to do is click Ok.

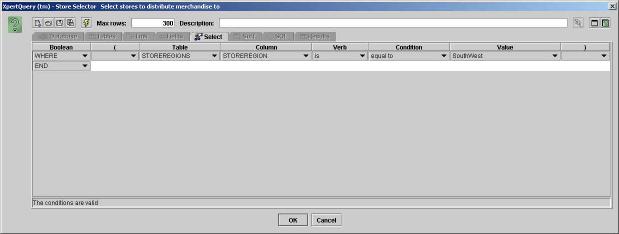

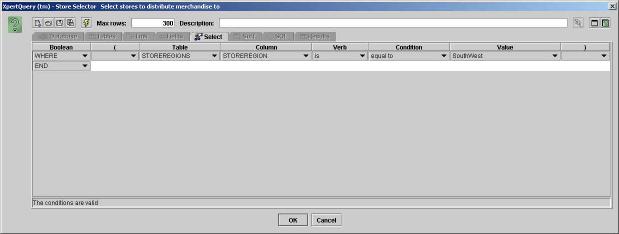

Both at the main or a remote you can choose the stores to which

the merchandise will be distributed. In order to do this the next

window will display a Store Selector to choose to which stores the

merchandise will be sent to. You can see the store selector here:

If you wish to send merchandise to all the stores then all you

have to do is click on Ok. If you only want to send merchandise to some

stores then you use the store selector to choose to which stores. It is

important to note that you will get a more optimum distribution if you

distribute to several stores at a time because Autodistribution can

then decide which is the store that most requires the

merchandise.

The

Autodistribution process generates Slips as an output be they Out Slips

or Proposed Out Slips. If you directly make Out Slips then all you have

to do is gather up actual merchandise and send it with the Out Slips to

the stores specified in the Out Slips.

If

Autodistribution generated Proposed Out Slips at the main then these

Proposed Out Slips will be synchronized out to each store. If the

process created Proposed Out Slips at a remote then they are right

there in the database at the store.

You can

look at the Proposed Out Slips under Documents / Transfers / Proposed

Slips (or Proposed Prepack Slips). There you can also run reports to

see what Proposed Slips you have.

To make a

transfer based on a Proposed Out Slip we open Transactions / Transfers

/ Out Slips. On the left top part we see the field Proposed Out Slip

Number as can be seen in this screen shot.

Once you write the Proposed Slip number in this field the system

is going to look for this proposed slip. If the systems finds the

Proposed Slip then it is doing to fill in the Out Slip on the screen

with all the items and information from the Proposed Slip. Then you

will be able to edit quantities, erase or add lines as you wish.

Ideally you would just gather exactly what is specified on the

Out Slip to transfer it and only make a change if you cannot find an

item specified on the Out Slip. Why? Remember that Auto Distribution

has taken into account a lot more information than you may have at hand

to decide to make this transfer.

End.